Understanding Engine Parts Manufacturers and Their Impact on the Automotive Industry

The world of engine parts manufacturers is a fascinating landscape that serves as the backbone of the automotive industry. As vehicles become more sophisticated, the demand for high-quality engine components continues to grow exponentially. In this comprehensive article, we will delve deep into the roles, significance, and operations of engine parts manufacturers, offering insights that are vital for anyone involved in the automotive sector or those with a keen interest in understanding how their vehicles operate.

What Are Engine Parts Manufacturers?

Engine parts manufacturers are companies specialized in producing various components that make up automotive engines. These manufacturers are crucial in supplying parts that ensure engines run smoothly, efficiently, and reliably. The components produced by these manufacturers can range from simple items like gaskets to complex pieces such as crankshafts and turbochargers.

The Importance of Engine Parts Quality

The quality of engine parts can significantly influence a vehicle's overall performance. Here are some reasons why the role of engine parts manufacturers is critical:

- Performance: High-quality engine components enhance engine performance, leading to better acceleration, fuel efficiency, and responsiveness.

- Safety: Reliable parts ensure that engines operate safely, reducing the risk of breakdowns and accidents.

- Longevity: Durable parts contribute to the overall lifespan of the engine, minimizing the need for repairs and replacements.

- Environment: Efficient engine parts lead to lower emissions, contributing to a cleaner environment.

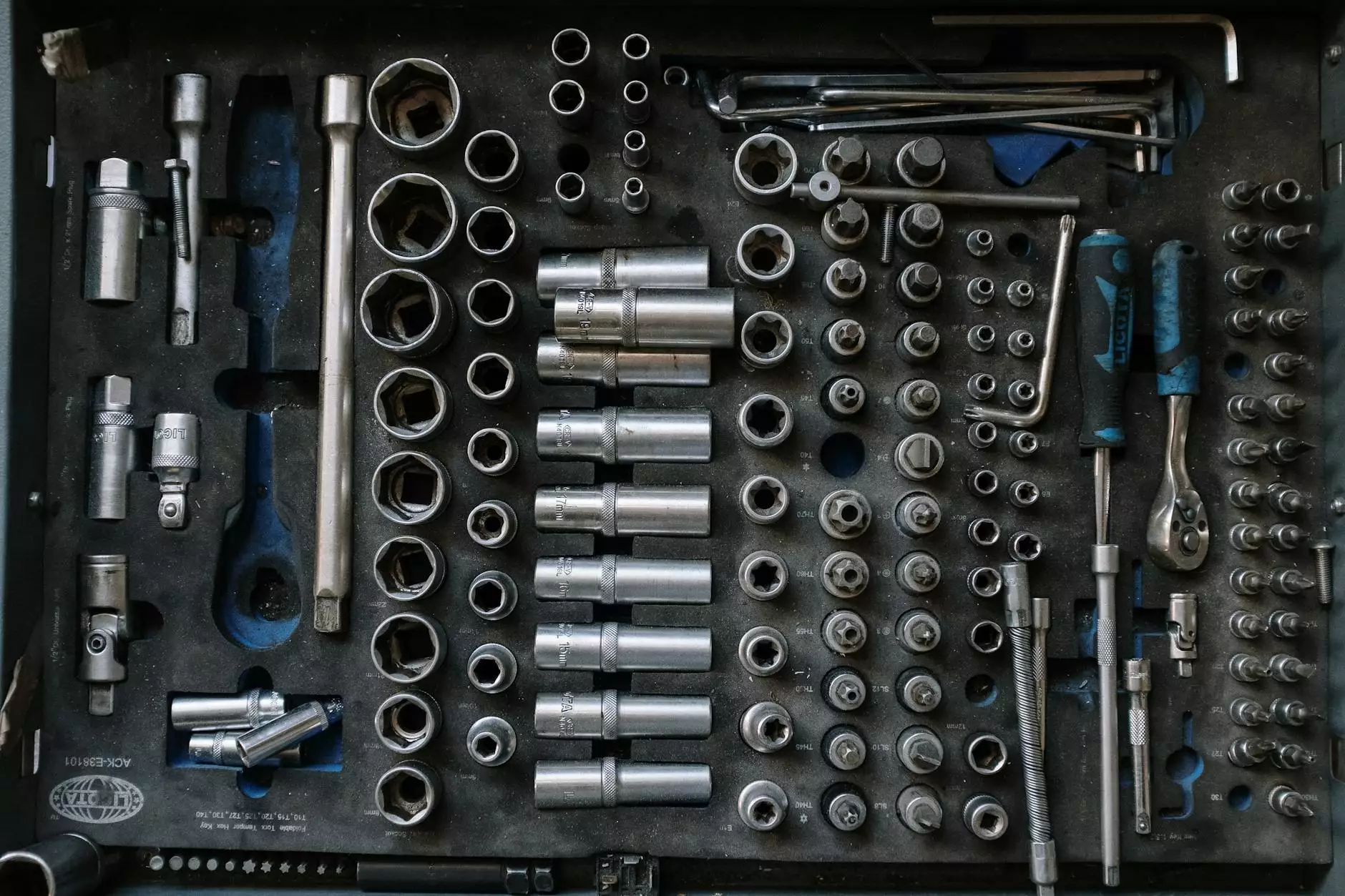

Types of Engine Parts Manufactured

Engine parts manufacturers produce a diverse array of components designed to meet the specific needs of different vehicles. Below is a detailed list of common types of engine parts:

- Engine Blocks: The core component of an engine, housing most of the engine parts.

- Pistons: Move up and down within the engine cylinder, creating the necessary pressure for combustion.

- Cylinders: Contain the pistons and are where combustion occurs.

- Cylinder Heads: Seal the top of the cylinders and house valves that control air and fuel intake/output.

- Crankshafts: Convert the linear motion of the pistons into rotational motion used to power the vehicle.

- Camshafts: Control the timing of the opening and closing of the valves.

- Gaskets: Provide a seal between various engine components, preventing leaks.

- Fuel Injectors: Precisely deliver fuel into the combustion chamber for efficient burning.

- Turbochargers: Increase the engine’s efficiency and power output by forcing extra air into the combustion chamber.

How Are Engine Parts Manufactured?

Understanding the manufacturing process of engine parts is essential for appreciating the level of precision and technology involved. Here is an overview of the key steps involved in the manufacturing of engine components:

1. Design and Engineering

The first step involves thorough research and development to design the parts according to industry specifications. Engineers utilize computer-aided design (CAD) software to create detailed models of the components.

2. Material Selection

Choosing the right materials is crucial for durability and performance. Common materials used include aluminum for lightweight components, and cast iron for parts requiring strength and stability.

3. Manufacturing Processes

Engine parts are produced using various manufacturing techniques including:

- Machining: Removing material from a solid block to create precise components.

- Casting: Pouring molten metal into molds to form parts like engine blocks and cylinder heads.

- Forging: Shaping metal using compressive forces, often used for crankshafts and connecting rods.

4. Quality Control

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure that each component meets the required specifications. This may involve dimensional inspections, material tests, and performance evaluations.

The Role of Technology in Engine Parts Manufacturing

Modern engine parts manufacturers heavily rely on advanced technological tools to enhance efficiency, precision, and throughput. Some key technologies utilized include:

- 3D Printing: Used for creating prototype parts or even final components, allowing for rapid prototyping and customization.

- Robotics: Employed in the assembly line to improve speed and reduce human error.

- Automation: Streamlines various processes, resulting in enhanced productivity and reduced costs.

- IoT (Internet of Things): Connected devices provide real-time data analytics and improve quality assurance.

Choosing the Right Engine Parts Manufacturer

For automotive businesses and mechanics, selecting the right engine parts manufacturer is paramount. Here are some crucial factors to consider:

1. Reputation and Reliability

Research the manufacturer’s reputation in the industry. Reviews, testimonials, and case studies can provide insight into their reliability and product quality.

2. Quality Standards

Ensure that the manufacturer complies with international quality standards such as ISO 9001, which guarantee that products meet specific management and quality assurance criteria.

3. Technology and Innovation

Assess the manufacturer's investment in technology. Companies that utilize advanced manufacturing techniques are likely to produce higher-quality components.

4. Customer Support

Effective communication and support are vital. A manufacturer that offers robust customer service can assist in troubleshooting and provide necessary guidance.

5. Pricing and Delivery

Analyze the pricing structures and delivery schedules to ensure they align with your business needs. Quality should not be compromised for cost, however.

The Future of Engine Parts Manufacturing

The automotive industry is undergoing a transformative phase with the rise of electric vehicles (EVs), hybrid technologies, and stringent emission regulations. How will this affect engine parts manufacturers?

- Shift to EV Components: Manufacturers will need to adapt their production lines to focus more on electric engines and associated components.

- Sustainability: Increasing emphasis on using recycled materials and eco-friendly production processes to meet regulatory standards.

- Innovation: As vehicles evolve, manufacturers will continually invest in research to develop new, advanced materials and components.

Conclusion

Engine parts manufacturers play a pivotal role in the automotive industry, impacting everything from performance to safety and sustainability. Understanding their operations, the types of parts they produce, and the technology they utilize is essential for anyone involved in the automotive sector. As the industry evolves, the importance of quality and innovation from these manufacturers will continue to grow, ensuring that vehicles remain efficient, safe, and environmentally friendly.

For those interested in exploring quality automotive components, visit imautoparts.com to discover a range of products that cater to your needs, ensuring you have access to top-tier parts that exemplify the best in manufacturing excellence.